BSWA - Cheese Making & Whisky Making are the same!

Searching in the rain for Sgriob-ruadh Farm, Home of Isle of Mull Cheese, I took a lift from Chris, who turns out to be the owner of the place.

They make Whisky Cheese, amongst others, and a more natural, harmonious pairing one is hard pushed to find.

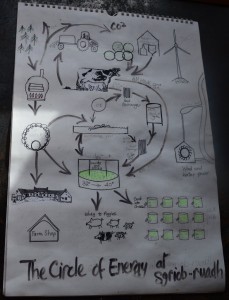

This place is eco friendly and self sustaining. It runs by itself, for itself, in a very old fashioned, completely up-to-date, circle of life, sustainable way.

They feed their herd of 130 Ayrshire cows draff from Tobermory Distillery. They milk 100 cows at a time, twice a day, every day of the year. They make cheese 3-5 times a week, so the milk must be stored.

The milk comes out the cows’ udders at 32 C, but needs to be stored at 5 C. The heat difference is stored in the water of a swimming pool at the farm, which is available for guests to use.

How excellent is this? Swim in a pool heated by cows milk ~ Cleopatra was never in it…..

The process begins by adding cheese culture to the milk to boost it’s natural bacteria, rennet is also added to encourage curdling. It then separates into curds and whey.

The whey is used as food for the pigs, but Chris has a new plan involving Juniper and distilling…….

The curds are kept and salt is added for preserving. It is squeezed into buckets and pressed for two days. Muslin and Cheesecloth bandages are wrapped on and the cheese is pressed for another day. What comes out at the end is a Truckle of Cheese. It takes 270 ltrs of milk to make a 26 kg Truckle of Cheese.

Only ‘keeping’ cheese is pressed. The magic of cheese, as of whisky, is that it is a living product. Very minute changes in the recipe can make a huge difference to the cheese/whisky at the end.

The cheese is dipped in scalding hot water to form a skin around it to seal it. It is also wrapped in two layers of muslin. It is stored on wooden shelves in a cellar for up to 18 months.

Each cheese is turned every two weeks, the temperature in the cheese cellar needs to be between 12 -15 and there must be constant air movement. The cheeses go throught different stages and need to be closely monitored and cared for, the same way we look after our whisky casks.

When a truckle is first stored it weights around 26Kg, but over time the moisture evaporates, at the end it weights 25 kg. A cheese can lose up to 2% moisture in a year. This loss is similar to whisky casks stored in a warehouse ~ we call this ‘The Angels’ Share’.

Whisky making was traditionally done on farms, as part of the circle of life. An excess of good grass in the summer translates to much milk, and so this is stored in cheese. An excess of barley translates to creation of malt which is then used to make uisge beatha ~ whisky.

Visiting the Mull Cheese Farm Sgriob-ruadh (red furrow) reminds me of the ways of the past, when whisky making was a natural part of life, not the commercial leviathan it has become.

I hope we will see a return to very small stills and people making uisge beatha for domestic consumption ~ similar to cider making in Somerset.

That my visit to Sgriob-ruadhhas re enforced my domestic stills philosophy is strangely fitting, considering Chris Reade told me that she and her husband came to Mull from Somerset….

Slainte!